Predictive analytics is essential for smart manufacturing due to the fact that manufacturing analytics relies upon predictive analytics. The need for real-time forecasting capabilities is a key driver of smart manufacturing, as it facilitates quality assurance, inventory management, and anomaly detection. Often, data scientists build models by hand, undergoing a drawn-out process that includes data preparation, model building, model deployment, and model execution. These handcrafted models are not scalable.

Table of Contents

Predictive analytics improves visibility

Predictive analytics improves visibility in manufacturing, a process whereby data about supply and demand patterns is analyzed to make predictions about future outcomes. Using this technology in manufacturing can eliminate overages and shortages and ensure that customer orders are fulfilled on time. However, some planners and managers are wary of this process, as it may be another data analysis model. While this may be true, the competitive advantages of implementing this type of technology outweigh the discomfort.

Predictive analytics can help a wide range of manufacturing companies. However, it is precious when applied to a specific operation. It can improve the visibility of entire supply chains and can help manufacturers better manage the processes of their production facilities.

Reduces maintenance and quality issues

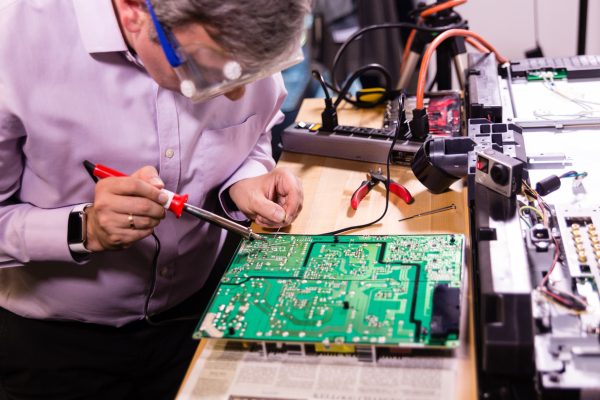

Predictive analytics is a powerful tool that helps manufacturers identify potential problems and improve their processes. It can help identify which equipment will break down, which strategies need improvement and which machines can be integrated with new machinery. The factory floor is undergoing major changes due to implementing Industry 4.0-compliant systems. Introducing such machinery is costly and requires careful planning and implementation to ensure positive results.

Traditionally, maintenance in manufacturing facilities is performed on a fixed cycle, with scheduled maintenance that involves checking and planning downtime for more in-depth maintenance. The end result is that parts may need to be replaced too early or too late, resulting in unnecessary downtime and maintenance. Predictive analytics detect defects before they manifest themselves and alert manufacturing teams to the need for immediate maintenance. Furthermore, it prevents unnecessary downtime and maintenance.

Optimizes machine throughput and output

Predictive analytics enables retailers to reduce costs by tracking machine performance and predicting when they will break down. It can also decrease transportation and shipping expenses. Here are four applications where predictive analytics is useful. All of them require data collection, integration, and formatting. You need to understand how these data are used to get the most out of these applications. Listed below are the three most important types of data and how they can help your business.

Predictive analytics is a way to improve performance and productivity by making predictions and prescribing the correct settings for controllable variables. It can help you maximize production runs and product quality and can even identify problems before they impact a machine’s performance. This kind of analytics is not for everyone, however, so the investment may not be right for all factories. However, before you start using predictive analytics, make sure that your workforce is data-literate and ready to use it.

Improves labor acquisition

Predictive analytics has become an indispensable tool in the manufacturing sector, as it helps develop key processes, such as product manufacturing, testing, and repair. Companies that use predictive analytics are able to maximize efficiency in these processes while also lowering costs and maximizing profitability. As a result, the term “predictive analytics” is usually reserved for business applications. However, many of the core analytical techniques used by predictive analytics companies are equally applicable in other industries.